Motion controller is a core element of a CNC machine, which allows it to work smoothly and efficiently. It enables precise, consistent, and fully automatized movement. With the assistance of a suitable control software, motion controller supervises the movements of the CNC machine’s elements, ensuring the correctness of the operations.

The applications of the CNC motion controllers

The CNC motion controllers position the tool in a strictly defined point in the relation to the workpiece. They work best, sustaining the collision-free motion, at maximum speed and maintaining the straight line. The CNC motion controllers are commonly used in various industries, mostly in:

- timber industry,

- electronics industry,

- automotive industry,

- aviation industry,

as well as food and pharmaceuticals industries, where they are being applied mostly in machines where it is essential to position the tool over the axis of a hole – drills, boring and perforating machines.

The types of the CNC motion controllers

There are different motion controllers available on the market, that can be divided into three main categories:

- microcontrollers, which are integrated on single electronic circuits,

- autonomous controllers, which are complete systems that feature electronics, power supply, and external connections in a single container,

- PC based controllers, which are mounted on the motherboard of a PC to generate and execute motion profiles.

PC based controllers are very common due to their availability and sustainability. Just by connecting them to the PC and installing an appropriate control software, such as Mach3, Mach4, or simCNC, the user can supervise the correctness of any given CNC appliance operation. The PC based CNC motion controllers can be further divided into 4-axis controllers, such as CSMIO/IP-M, and 6-axis controllers, such as CSMIO/IP-S.

CSMIO/IP-M Motion Controller

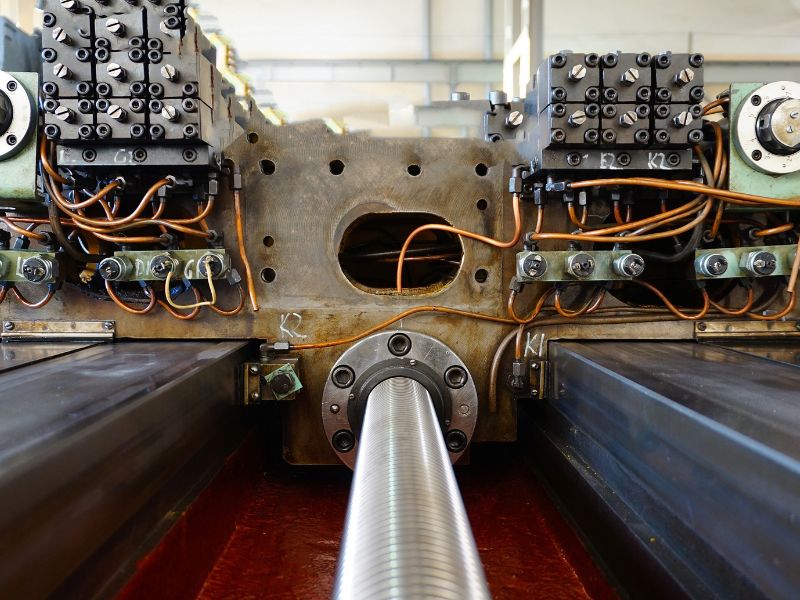

CSMIO/IP-M Motion Controller (STEP/DIR) is a 4-axis CNC control system. It is recommended for the users who retrofit original CNC machines that require a lower number of digital signals for basic signals support, as well as build new milling machines or any size routers that reach satisfactory speed and accuracy. CSMIO/IP-M motion controllers can be used with milling machines, routers, plasma and laser cutters, and lathes that don’t require threading function. They can be extended with additional module CSMIO-MPG.

CSMIO/IP-S Motion Controller

CSMIO/IP-S Motion Controller (STEP/DIR) is a 6-axis CNC control system. It is recommended for the users who retrofit original CNC machines that require a large number of digital signals for tool magazines or automatic transmission support, build new, fast and precise milling machines or routers equipped with a high frequency of step/dir signal servo drives, build very large machines equipped with riding gantry, and plan to develop their control system in the future, by implementing additional modules. CSMIO/IP-S is a motion controller perfectly fitted for milling machines, lathes, routers, plasma and laser cutters.

How to choose a suitable motion controller?

Motion controller determines the overall performance of a motion system. It means that, in order to obtain the desirable performance, the user needs to choose a suitable motion controller, which is application-specified and matches both the characteristics of the machine, and the requirements of the project. Before purchasing the controller, the user needs to familiarize himself/herself with the various options available on the market.

It is necessary to determine the most effective solution, taking under consideration the level of coordination, the type of application, and such variables, as mass, move, and means. In order to choose a suitable motion controller, the user should establish:

- what is supposed to be moved,

- what is used to move the object,

- the required speed of movement,

- the dynamics of the process,

- the profile of the move.

CS-LAB offers the best CNC controllers of the highest quality, recommended for professionals, automation producers, retrofit specialists, and hobbyists in need of solid, flexible, and compact control systems. The motion controllers in CS-LAB’s offer are eligible for expansion with dedicated module expansions.

Greenzoner.com

Greenzoner.com

Leave a Reply